Nanoimprint Lithography (NIL)

For series production of nanostructured and microstructured films and plates, we at temicon use various UV nanoimprint systems. Our production facilities allow a roll-to-roll or roll-to-plate process.

For series production, temicon scores with speed and a wide range of formats.

Nanoimprinting at temicon

Nanoimprint lithography, or NIL for short, is an innovative process for replicating microstructures and nanostructures, especially on large surfaces. With state-of-the-art equipment and comprehensive know-how from renowned projects, temicon is your competent partner.

Nanoimprint Molds / Stamps for your product ideas

The starting point for the process of nanoimprint lithography is the imprint tool. The tool is used to replicate the nano- or microstructures. It contains the form of the structures that will appear on the final product. Thus, the imprint tool represents a stamp. The tool is referred to as a 'mold' or 'stamp'.

temicon has many years of experience in the development, prototyping and application of nanoimprint molds for the mass production of surface structures for applications in areas such as display, lighting, solar or optics.

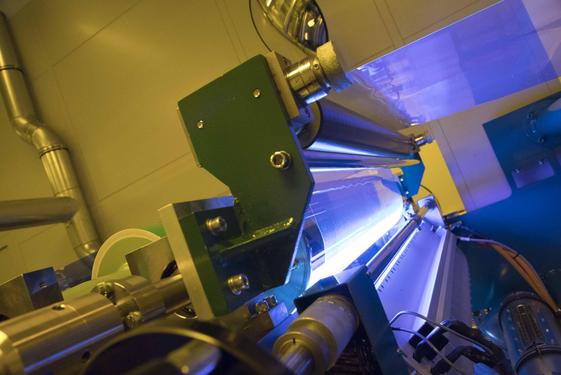

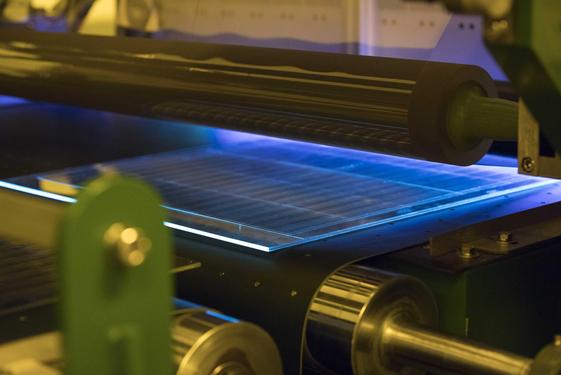

Roll-to-roll series production at temicon

The production of microstructured or nanostructured surfaces using nanoimprint lithography is carried out on our state-of-the-art roll-to-roll equipment. This manufacturing process enables a particularly cost-effective and fast series production.

Roll-to-roll manufacturing

Wide product range – versatile solutions

Are you looking for a partner for large-area and cost-effective nanostructuring and microstructuring? As our customer, you benefit from our unique roll-to-roll production lines and the comprehensive know-how of a technology leader in the nanoimprinting process.

temicon turns your product ideas into reality. From the initial feasibility study to industrial mass production. For the cost-effective series production of nanostructured and microstructured films and sheets, we have different roll-to-roll or roll-to-plate lines available, depending on your requirements.

With this technology, we serve the following industries:

In technical literature, the roll-to-roll process is abbreviated as R2R. The special temicon technology is called R2R NIL: Combining "roll-to-roll" with "nano-imprint lithography" (NIL). The roll-to-roll manufacturing process with multiple rolls enables cost-effective nanostructuring or microstructuring of flexible surfaces with high throughput.

In UV nanoimprint, replication of microstructures or nanostructures is done using a UV-curable polymer. This UV-curable resin layer applied to the substrate is used in the roll-to-roll process as an intermediate layer between the stamp and the substrate to pattern the film.

Roll-to-roll coating enables seamless replication and consistent layer thickness. The imprint tool used can be reused for subsequent nanoimprinting production.

Nano- and microstructures as desired

It is possible to imprint structures with sizes ranging from a few nanometers to 200 µm. Films with thicknesses between 36 µm and 250 µm and widths of up to 1150 mm can be used. The maximum structure width is 1050 mm.

Roll-to-Plate

In addition to the roll-to-roll process (R2R), we offer nanoimprinting as a roll-to-plate process (R2P). This means that in addition to films, rigid materials can also be structured at temicon using nanoimprint lithography.

As in the roll-to-roll process, a synthetic resin cured by UV light serves as an intermediate layer for the lithographic imprint of the nanostructures in the R2P NIL process.

UV-Nanoimprint

temicon specifically uses the UV nanoimprint lithography (UV-NIL) process. For this, a UV-curing polymer layer is used.

While the surface with the initially still uncured polymer layer is in contact with the imprint tool on the roll-to-roll system, the nanostructures or microstructures are transferred to the surface by means of UV light.

36µm

1050mm

1m x 1,6m

Consultation

We will be happy to advise you.

Which nano- or microstructures would you like for your products? Call us! Benefit from our expertise