Life Science

In medical technology, nano- and microstructures open new possibilities in analysis and therapy or improve existing methods.

They are used in microfluidics (lab-on-a-chip and lab-on-a-film), creation of aerosols (spray nozzles), filtration of materials and liquids (filters and membranes), in cell analysis and breeding of cell cultures (titer plates).

Katrin Christiani

Product Manager Life Science

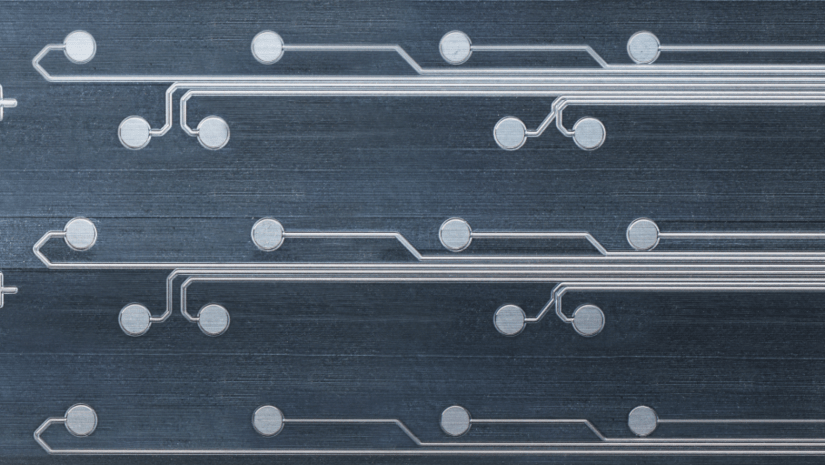

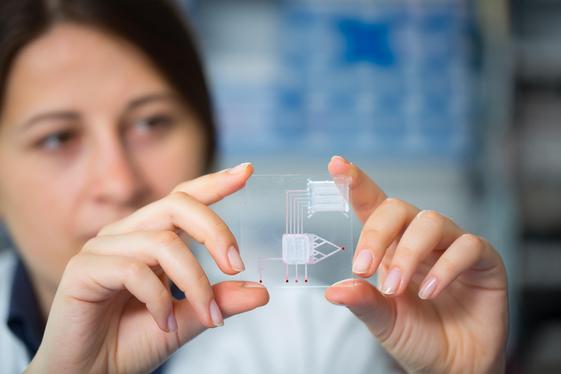

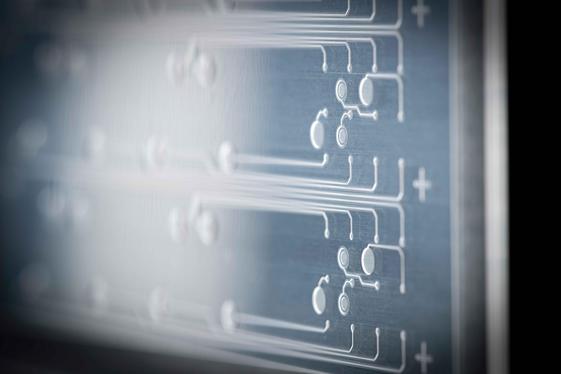

MICROFLUIDIC CHIPS

Microfluidic structures as lab-on-a-chip and lab-on-a-film

Microfluidic structures are used in medical technology and allow investigation or control of the tiniest quantities of fluid, within the nano-liter range.

Producing micro-channels and cavities often pushes conventional machining technology to its limits. As a producer of lithographically manufactured microfluidic structures, temicon offers the advantages of tiny, highly precise structure dimensions, low roughness values and minimal edge rounding. Due to worldwide demand for faster, more cost-efficient diagnostics, use of microfluidic chips has become ever more important in recent years.

temicon offers tool development, prototyping and production of small series to series of 100,000+ parts that are cost-efficiently made by injection molding (lab-on-a-chip) or UV roll nano-imprint (lab-on-a-film).

1 week

100,000+

1µm

SPRAY NOZZLES

Spray nozzles for manufacturing aerosols in medical technology

In production of medical aerosols, but the droplet size and the narrowest possible droplet size distribution are crucial. When making micro-nozzles, temicon uses LIGA-technology to meet these important requirements. Burr-free production of nozzle plates makes it possible.

Various profiles can be chosen for the nozzle shape: round hole, two-level profile, trumpet profile. We produce cost-effective, customer specific spray nozzles in large quantities.

2µm

100%

10,000

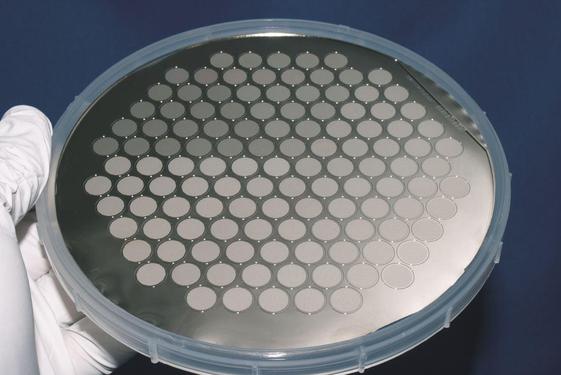

Microfilters and -membranes

Microfilters and -membranes

Microfilters and -membranes with hole or slit widths in the lower micrometer or sub-micrometer range are used in many applications. The micro-hole structures are used for filtration or separation, for example. Microorganisms from water or food, or pollutant particles from the air can be separated in this way. In other applications, microfilters are used to build particle concentrations for later analysis.

Our technology allows production of microfilter with trumpet profiles to prevent holes from clogging, among other things.

2µm

100%

10,000

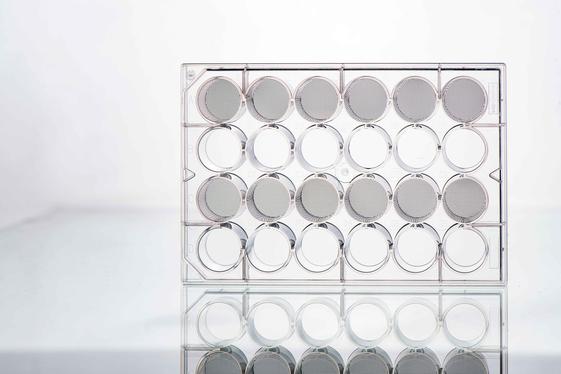

MICROTITER PLATES

Microstructured titer plates for in vitro analysis and cell growth

temicon produces customer-specific titer plates with microstructured surface for uses such as cell analysis, in vitro diagnosis, cell separation or improved cell cultivation. Our series production of microtiter plates is done with silicon casting or injection molding.

50nm

100%

2µm

Consultation

We will be happy to advise you.

Which nano- or microstructures would you like for your products? Call us! Benefit from our expertise